When designing safe and engaging play areas for children, commercial soft play equipment must be durable, easy to clean, and able to withstand heavy use. Manufacturers use a variety of high-quality materials to ensure safety, comfort, and longevity. Below, we explore the common materials used in soft play equipment and their benefits.

What Is Commercial Soft Play Equipment Made From?

1. High-Density Foam

The core component of most soft play structures is high-density foam, which provides cushioning to prevent injuries. Different types of foam are used depending on the application:

Polyurethane Foam (PU Foam):A flexible, resilient material often used in climbing blocks, slides, and play mats.

Ethylene-Vinyl Acetate (EVA Foam):A durable, waterproof foam commonly used for soft play tiles and modular shapes.

Cross-Linked Polyethylene (PE Foam):A firmer foam used in structural components like beams and stepping stones.

These foams are tested for impact absorption to meet safety standards such as ASTM F1918 and EN 1176.

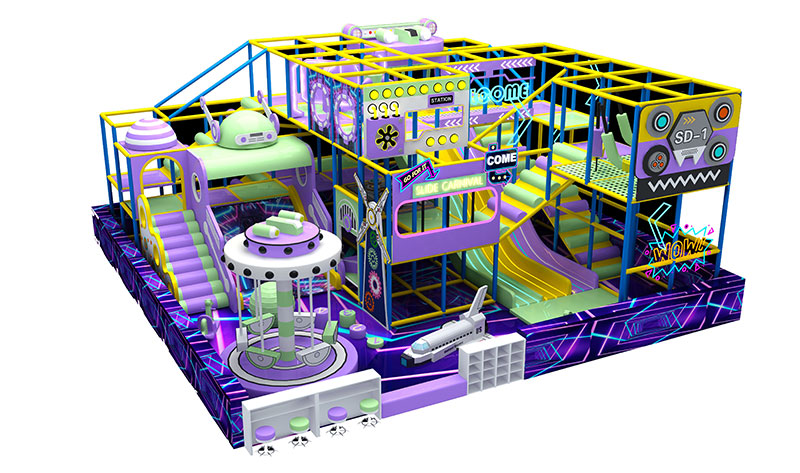

2. Vinyl or PVC Covering

To protect the foam and make cleaning easier, soft play equipment is typically wrapped in heavy-duty vinyl or PVC. These materials are:

Waterproof & Hygienic: Resistant to spills, sweat, and bacteria, making them ideal for commercial settings.

Easy to Clean:Can be wiped down with disinfectant solutions.

Tear-Resistant:Reinforced stitching and high-quality vinyl prevent rips from frequent use.

Some premium soft play equipment uses phthalate-free vinyl for added safety, especially in baby and toddler areas.

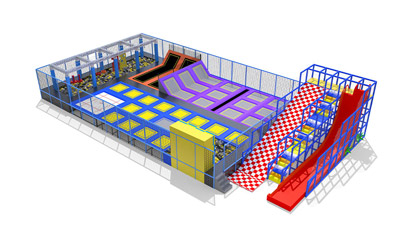

3. Plastic and Fiberglass Reinforcement

While the main structure is soft, some components require rigid materials for stability:

Rotomolded Plastic:Used for slides, tunnels, and climbing walls due to its strength and smooth surface.

Fiberglass:Lightweight yet sturdy, often used in custom-designed play structures.

These materials are often combined with foam padding to maintain a soft-play experience while ensuring structural integrity.

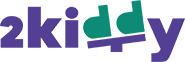

4. Steel Framing (For Larger Structures)

In large soft play installations, steel frames provide support for multi-level play systems. The metal is powder-coated to prevent rust and covered with foam padding to ensure safety.

5. Netting and Fabric Elements

Climbing nets, ball pit barriers, and tunnels often use:

Polyester or Nylon Rope: Strong, flexible, and resistant to wear.

Mesh Fabric: Breathable yet durable, allowing visibility while keeping children safe.

Why Material Choice Matters in Soft Play Equipment

Selecting the right materials ensures:

Safety – Impact-absorbing foams reduce injury risks.

Durability – Commercial-grade materials withstand heavy daily use.

Hygiene – Easy-to-clean surfaces prevent germ buildup.

Comfort – Soft yet supportive textures enhance play experiences.

Commercial soft play equipment is primarily made from high-density foam, vinyl/PVC covers, reinforced plastics, and sometimes steel framing for durability and safety.

Conclusion

Commercial soft play equipment is made from a combination of high-density foam, vinyl, plastic, and sometimes steel framing to create a safe, long-lasting play environment. By choosing quality materials, businesses can ensure their play areas remain fun, hygienic, and structurally sound for years.