For operators of Trampoline Parks, keeping equipment in good shape is key to visitor safety and long-term business stability. Yet many struggle to tell when to replace old/worn equipment: waiting too long risks safety, while replacing too early wastes resources. This article breaks down clear signs to help you decide.

Visible Wear on Key Components

Visible damage is the most direct sign equipment may need replacing. Not all wear requires action, but certain issues mean it can't function safely.

Trampoline Mats

Check for deep tears, frayed edges, or permanent stretching. If the surface loses non-slip texture, or holes over 1 inch form, replacement is needed. Damaged mats reduce bounce control and raise fall risks.

Springs and Frame

Rust that won't clean off, bent/broken springs, or springs losing tension call for replacement. For frames, cracks, warping dents, or loose joints that won't tighten mean it's time—compromised frames undermine overall stability.

Safety Padding and Enclosures

If padding tears open or foam flattens, replace it. For enclosures, ripped netting, broken zippers, or sagging poles are critical—enclosures are the first defense against falls outside the trampoline.

Changes in Performance or Safety Feel

Even without obvious damage, performance shifts can signal hidden issues.

Uneven Bounce

If some mat areas bounce much higher/lower, springs may be failing or the mat stretched unevenly. Uneven bounce increases balance loss and collision risks.

Unusual Noises

Persistent squeaks, creaks, or rattles often mean loose parts, worn bearings, or stressed components. If tightening bolts or lubrication doesn't stop the noise, the equipment may be structurally at risk.

Compliance with Updated Safety Standards

Safety standards for Trampoline Parks evolve to address new risks. Even functional equipment may no longer meet current rules.

Check local regulators or groups like ASTM/TUV for latest requirements. For example, if new standards demand thicker padding or taller enclosures, older equipment that doesn't comply should be replaced—avoiding legal risks and protecting visitors.

Frequency of Repairs

Frequent minor repairs mean equipment is near the end of its life.

If you fix the same part (e.g., spring, net section) multiple times in months, repair costs and time will soon surpass a new component. Frequent repairs also mean more downtime for the trampoline area, hurting operations.

Conclusion

Knowing when to replace Trampoline Parks equipment balances safety, cost, and user experience. By checking wear, monitoring performance, following standards, and tracking repairs, you can make timely choices to protect visitors and keep business smooth.

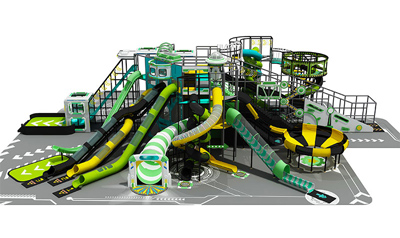

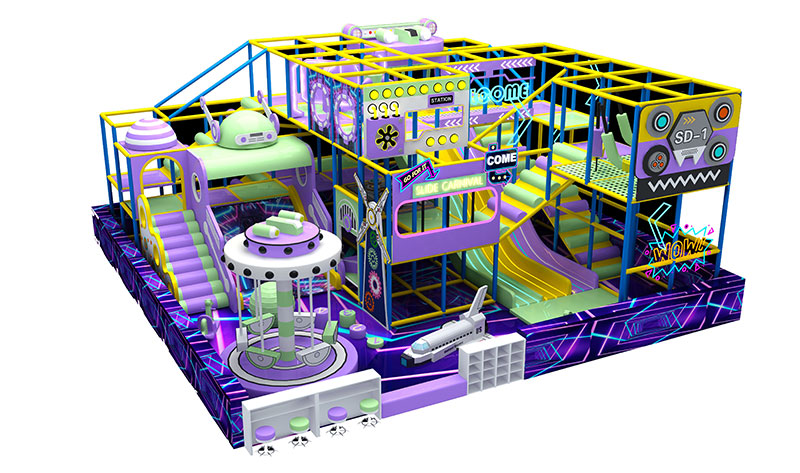

When replacement is needed, reliable, high-quality equipment is key. Explore our Trampoline Parks product line—designed to meet latest safety standards and built for durability—to support your operations. Visit our product page to learn more.